Spunlace fabric, also known as hydroentangled fabric, is a type of nonwoven fabric that is produced using a mechanical process called hydroentanglement. Unlike other nonwoven fabrics that are made by bonding fibers with chemicals or heat, spunlace fabric is created by entangling fibers together through the use of high-pressure water jets.

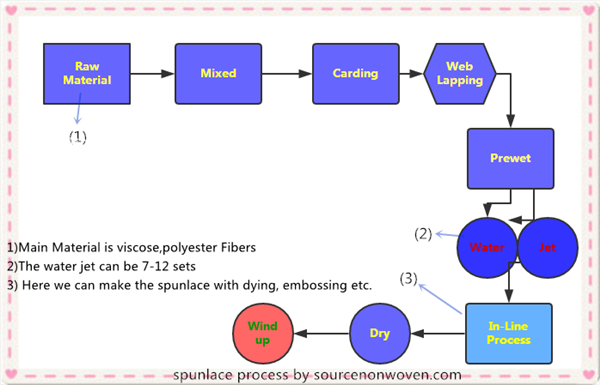

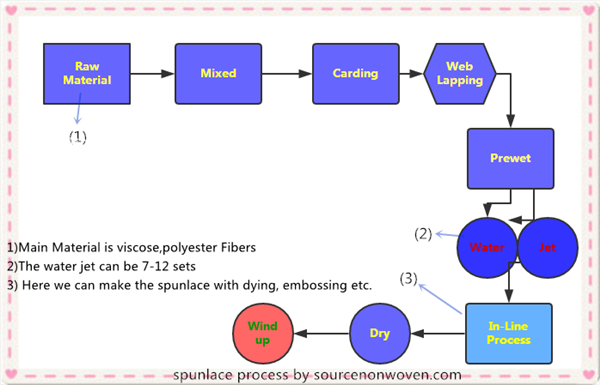

The process of producing spunlace fabric involves the following steps:

- Fiber Preparation: Natural or synthetic fibers, such as cotton, polyester, rayon, or a blend of different fibers, are first opened and blended to create a homogeneous fiber web.

- Web Formation: The fibers are then formed into a loose web using carding or airlaid techniques. This web serves as the starting material for the spunlace fabric.

- Hydroentanglement: The loose fiber web is passed through a series of high-pressure water jets that propel the fibers onto a moving conveyor belt or screen. The force of the water jets entangles the fibers together, creating a strong and cohesive fabric.

- Drying and Finishing: After the hydroentanglement process, the fabric is dried using heat or air, and then subjected to various finishing treatments, such as calendering or surface treatments, to improve its properties and appearance.

Spunlace Process

Spunlace fabric offers several advantages over other types of nonwoven fabrics:

- Softness: Spunlace fabric has a soft and smooth texture, making it comfortable to use in various applications, including personal care products, wipes, and medical textiles.

- Strength: The entangled fibers in spunlace fabric create a strong and durable material that can withstand rigorous use and handling.

- Absorbency: Spunlace fabric has excellent absorbent properties, making it suitable for applications that require high liquid absorption, such as wipes or medical dressings.

- Versatility: Spunlace fabric can be produced in different thicknesses, weights, and compositions, allowing it to be tailored to specific requirements and applications.

- Eco-friendly: The production of spunlace fabric consumes less energy and water compared to other nonwoven manufacturing processes, making it a more environmentally friendly option.

Spunlace fabric finds applications in various industries, including hygiene products, medical textiles, filtration, automotive, and cleaning wipes. Its unique combination of softness, strength, and absorbency makes it a preferred choice for many different end uses.